English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

News

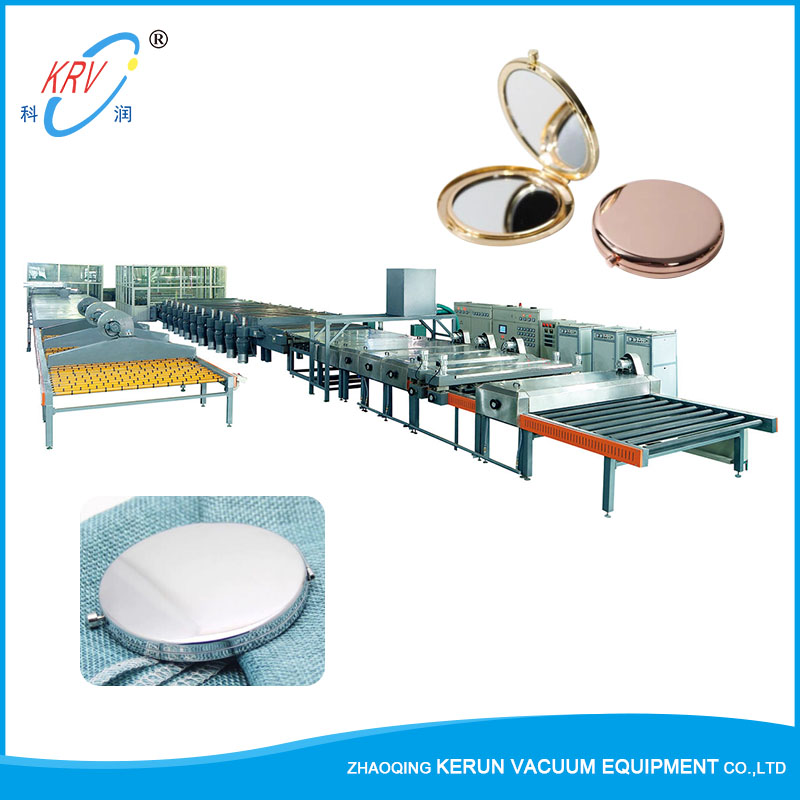

What is Aluminum Mirror Production Line

The Aluminum Mirror Production Line refers to a manufacturing system used for producing aluminum mirrors. The production process involves cutting sheets of aluminum to size, polishing them to obtain a smooth surface, and applying a reflective coating on one side.

Read MoreWhat are the ingredients in glass coating?

When applying or choosing a glass coating for your vehicle or other surfaces, it's essential to follow the manufacturer's instructions and recommendations to ensure proper performance and longevity. Additionally, safety precautions, such as adequate ventilation, should be taken when working with coa......

Read MoreWhat is the function of glass coating?

The functions of glass coating are as follows: 1. The function of preventing oxidation and aging of the paint surface: the real glass coating does not contain macroscopic petroleum components and will form a hard inorganic (glass crystal) film layer on the surface of the car paint after construction......

Read More