English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

High Pumping Speed Plastic Vacuum Coating Machine Manufacturers

With superior technologies and facilities, strict quality command, reasonable cost, exceptional provider and close co-operation with customers, we've been devoted to delivering the best benefit for our buyers for High Pumping Speed Plastic Vacuum Coating Machine,Vacuum Coating Machine for Plastic,Aluminum Metalizing Machine,Silver Reflector Vacuum Plating Machine,Evaporative Coating Device, We sincerely welcome friends to barter business enterprise and start cooperation with us. We hope to hitch hands with close friends in different industries to produce a brilliant long run.

High Pumping Speed Plastic Vacuum Coating Machine, We supply OEM services and replacement parts to meet the varying needs of our customers. We supply competitive price for quality goods and we are going to make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

Hot Products

ITO Film Winding Type High Vacuum Magnetron Coating Machine

ITO Film Winding Type High Vacuum Magnetron Coating Machine uses the driver motor to adjust the speed of the main roller, the winding roller and the unwinding roller of the flexible substrate material, and cooperates with its tension sensor to realize the film transmission process,is the first choice equipment for packaging industry and conductive industry. The products from the ITO film winding high vacuum magnetic coating machine can meet European CE standards. The Leading manufacturer in China.ITO Conductive Glass Coating Equipment

ITO conductive glass coating equipment is the first choice for the household appliance industry。Product Parameter is stainless steel, vertical, cooling water on the outer wall, with stainless steel lining baffle. has been successfully exported to more than 20 countries including European and American markets and enjoys high reputation so far.Auto Lamp Protective Film Coating Machine

The products from the auto lamp protective film coating machine can meet the European CE standard, is easy to operate and fully automatic control. Combining PVD and CVD technology on one set of equipment can achieve coating and spraying process in one time, can realize the coating of plastic products without bottom spraying and surface spraying.Glass High Vacuum Aluminum Mirror Coating Machine

The glass high vacuum aluminum mirror coating machine has reasonable structure, uniform film layer and good mirror quality, it widely used in construction industry and decoration industry. The products from the glass high vacuum aluminum mirror coating machine can meet the European CE standard. We have a top R&D team and Independent intellectual property.High-grade Environmental Protection Copper-free Silver Mirror Production Line

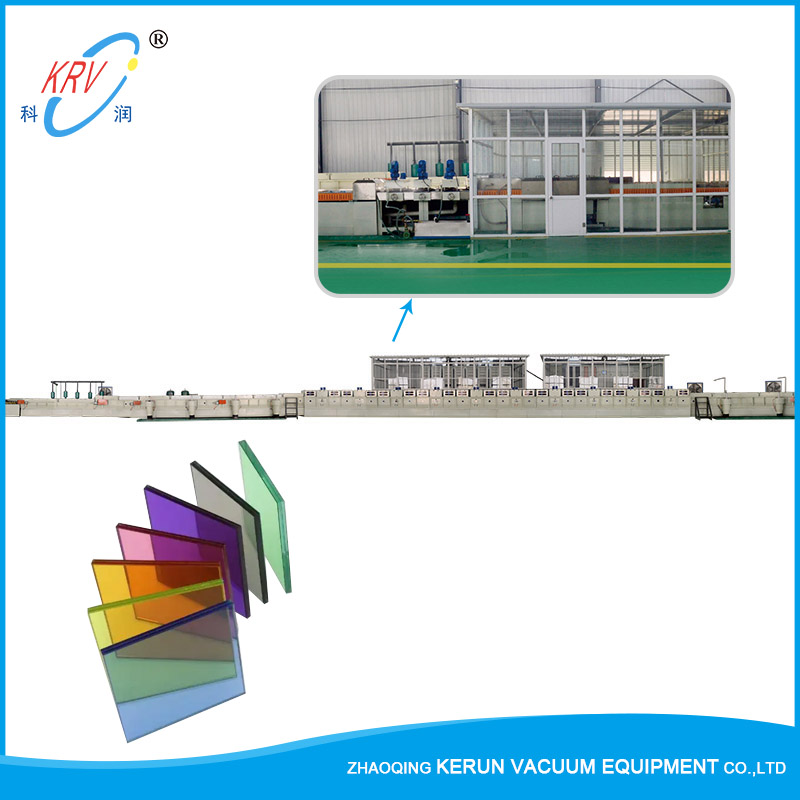

High-grade environmental protection copper-free silver mirror production line adopt chemical spraying method to plate the glass surface with silver film, passivation protection, and then paint one or two layers of paint film. adopt quartz infrared heating tube for oven drying. size and configuration can be customized according to customer requirementsHigh-grade Environmental Protection Copper-free Silver Mirror Equipment

Products from high-grade environmental protection copper-free silver mirror equipment can meet European CE standards,and silver mirror products are widely used in the construction industry. The whole production line adopts frequency conversion motor drive and running speed can be adjusted on color display screen.