English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

Evaporative Coating Device Manufacturers

We try for excellence, service the customers", hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for Evaporative Coating Device,Vacuum Coating Machine for Plastic,Aluminum Metalizing Machine,Silver Reflector Vacuum Plating Machine,High Pumping Speed Plastic Vacuum Coating Machine, Welcome any within your inquiries and concerns for our products and solutions, we glance ahead to setting up a long-term enterprise partnership along with you within the close to potential. get hold of us today.

Evaporative Coating Device, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

Hot Products

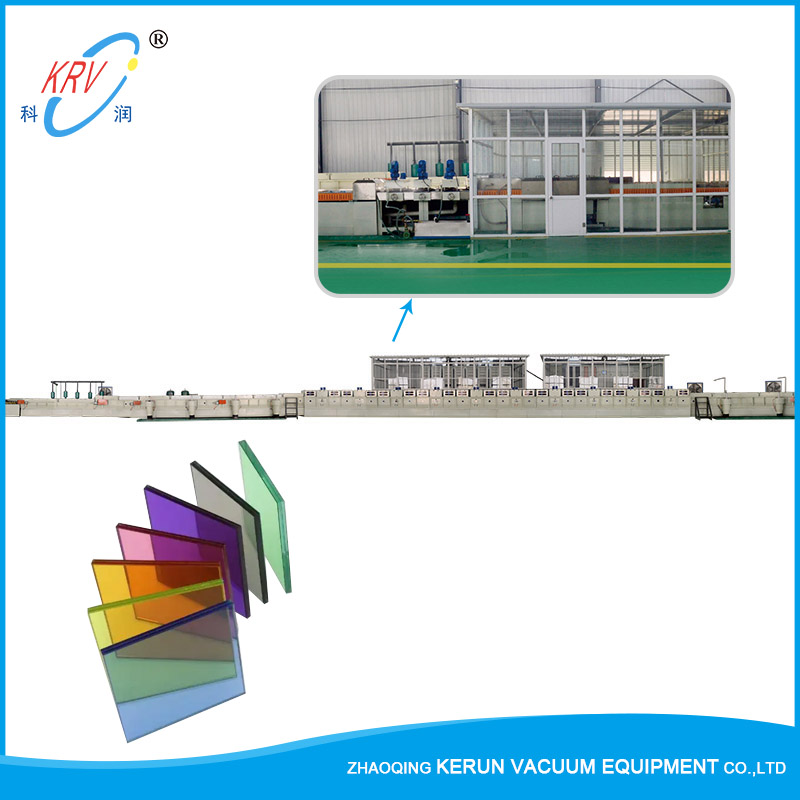

Glass Washing Machine

The glass washing machine specially designed and produced by Kerun Vacuum summarizes the experience of deep processing in the glass industry in recent years, studies and absorbs the advanced technologies and processes of domestic and foreign counterparts. It has reasonable cleaning technology, simple structure, convenient operation, good cleaning effect, low cleaning cost,etc. Special design and production can be carried out according to the requirement. We provide customized products service. If you want pricelist and quotation, you can ask us by leaving a message. We will get back to you as soon as possible.Vacuum Leak Detector

The vacuum leak detector has the characteristics of simple and accurate leak detection, are necessary equipment for the vacuum machines manufacturers and the vacuum machine Users. It has been successfully exported to more than 20 countries including European and American markets and enjoys high reputation so far. We are the Leading manufacturer in China.High Vacuum Winding Type Coating Equipment

The high vacuum winding type coating equipment is equipped with an efficient vacuum pumping system. The winding system adopts imported all-digital tension control system. The equipment is a special equipment for vacuum evaporation of aluminum film on the surface of film coil. We have a top R&D team and Independent intellectual property. size and configuration can be customized according to customer requirements.Large-scale Environmental Protection Aluminum Mirror Production Line

Large-scale environmental protection aluminum mirror production line With double-end structure, multi-chamber and multi-sputtering target configuration, all processing including glass washing , coating , flow painting , drying and air-cooling can be finished at one time with high efficiency and lower labor cost. dopts fully automatic control system to ensure production safety and stable quality . The Leading aluminum mirror production line manufacturer in China.Multi-arc Magnetic Ion Coating Machine

Multi-arc magnetic ion coating machine uses programmable logic controller (PLC), automatic or manual optional. This series of equipment is mainly suitable for coating the surface of metal parts, hardware, etc. One layer or multi-layer metal film. For example, high-grade decorative films such as TIN film and imitation gold film, gold-doped film, gun black film, etc. Has been successfully exported to more than 20 countries including European and American markets and enjoys high reputation so far.High-grade Environmental Protection Copper-free Silver Mirror Equipment

Products from high-grade environmental protection copper-free silver mirror equipment can meet European CE standards,and silver mirror products are widely used in the construction industry. The whole production line adopts frequency conversion motor drive and running speed can be adjusted on color display screen.