English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

Low Energy Consumption Plastic Vacuum Coating Machine Manufacturers

We are proud of the superior customer gratification and wide acceptance due to our persistent pursuit of top of the range both of those on merchandise and service for Low Energy Consumption Plastic Vacuum Coating Machine,Vacuum Coating Machine for Plastic,Aluminum Metalizing Machine,Silver Reflector Vacuum Plating Machine,Evaporative Coating Device, We're very proud of your fantastic popularity from our prospects for our products' reputable quality.

Low Energy Consumption Plastic Vacuum Coating Machine, We put the product quality and customer's benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, let us work together to get success.

Hot Products

High-grade Environmental Protection Copper-free Silver Mirror Equipment

Products from high-grade environmental protection copper-free silver mirror equipment can meet European CE standards,and silver mirror products are widely used in the construction industry. The whole production line adopts frequency conversion motor drive and running speed can be adjusted on color display screen.Multi-arc Magnetic Ion Coating Machine

Multi-arc magnetic ion coating machine uses programmable logic controller (PLC), automatic or manual optional. This series of equipment is mainly suitable for coating the surface of metal parts, hardware, etc. One layer or multi-layer metal film. For example, high-grade decorative films such as TIN film and imitation gold film, gold-doped film, gun black film, etc. Has been successfully exported to more than 20 countries including European and American markets and enjoys high reputation so far.High Vacuum Winding Type Coating Equipment

The high vacuum winding type coating equipment is equipped with an efficient vacuum pumping system. The winding system adopts imported all-digital tension control system. The equipment is a special equipment for vacuum evaporation of aluminum film on the surface of film coil. We have a top R&D team and Independent intellectual property. size and configuration can be customized according to customer requirements.Automobile Rearview Mirror Blue Film Production Line

Automobile rearview mirror blue film production line is mainly composed of other films such as chrome mirrors and blue mirrors. It has high production efficiency, simple process control and convenient maintenance. The mirror is not deformed, no pitting or other defects. We have a high-quality products and efficient, convenient and comprehensive pre-sales and after-sales professional services.Aluminum Mirror Vacuum Coating Equipment

The products from the Aluminum Mirror Vacuum Coating Equipment can meet the European CE standard. And widely used in the High-class silver mirror production line with complete set of technology. We has invitedexperts to join the Vacuum Coating R&D centre which target at developing the most advancedvacuum coating equipment.Stained Glass Magnetic Coating Equipment

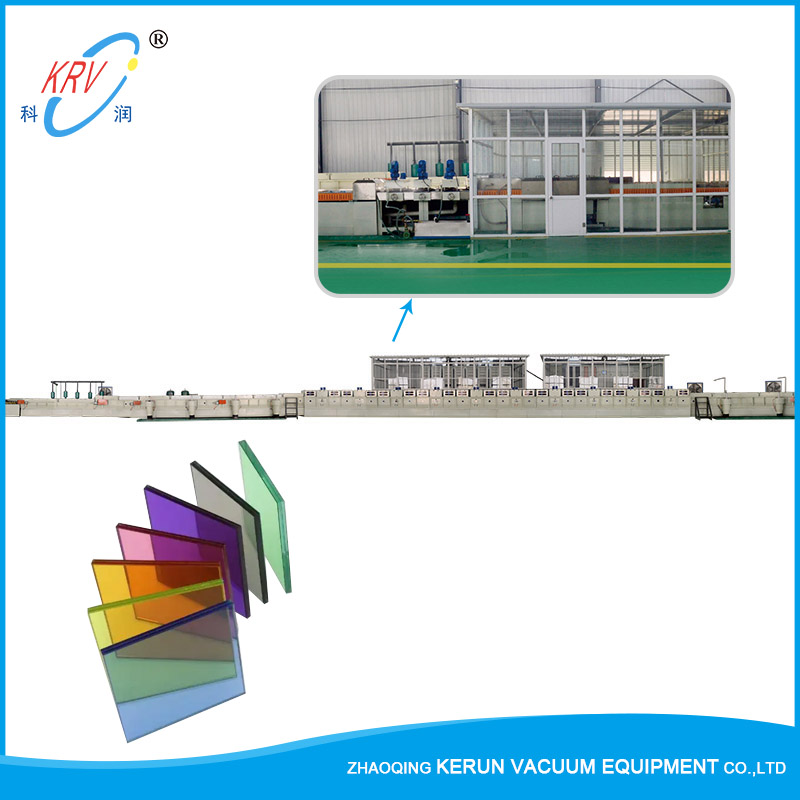

Stained glass magnetic coating equipment size and configuration can be customized according to customer requirements. We have professional sales team and dedicated service team. Stained glass magnetic coating equipment has single-end and double-end structure.