English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

Stable Performance Plastic Vacuum Coating Machine Manufacturers

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for Stable Performance Plastic Vacuum Coating Machine,Vacuum Coating Machine for Plastic,Aluminum Metalizing Machine,Silver Reflector Vacuum Plating Machine,Evaporative Coating Device, If you are fascinated in any solutions, you should experience absolutely free to make contact with us for additional details or you should send out us email instantly, we will reply you within just 24 hours and also the best quotation might be provided.

Stable Performance Plastic Vacuum Coating Machine, If you are for any reason unsure which product to select, do not hesitate to contact us and we'll be delighted to advise and assist you. This way we will be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We're looking for more and more customers to create the glorious future.

Hot Products

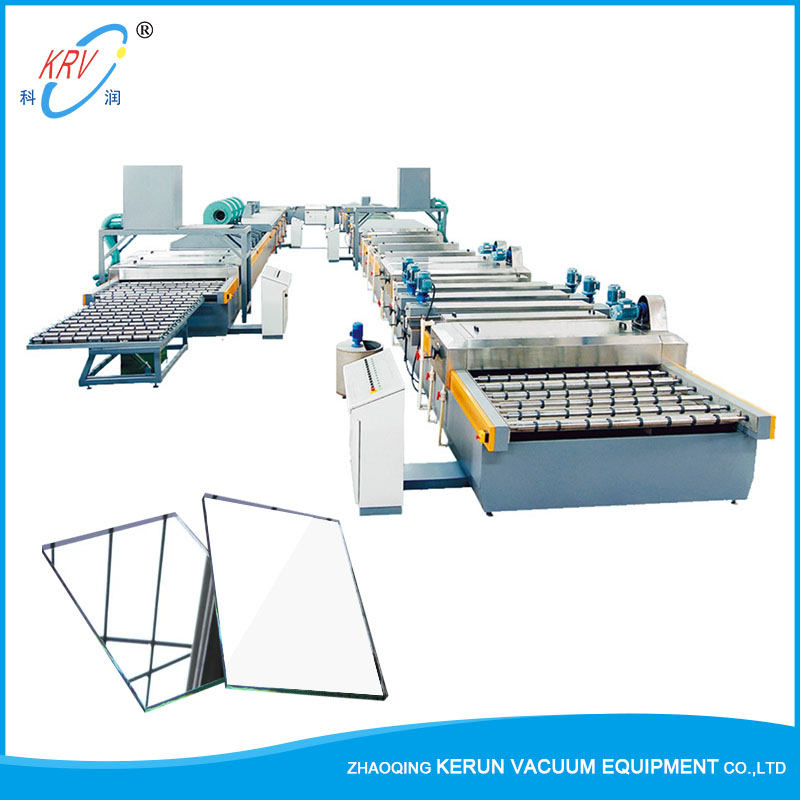

High-grade Silver Mirror Production Line

The high-grade silver mirror production line from the glass loading, then to glass washing, silver plating, copper plating, painting, baking, repainting, baking, washing, mark printing, and testing, finish in one time, the silver mirror can be packed after unloading. It is driven by a variable frequency speed regulation motor, and the running speed can be adjusted from the color display. The Leading silver mirror production line manufacturer in China.Chip Resistance Terminal Magnetic Sputtering Coating Machine

Chip resistance Terminal Magnetic Sputtering Coating Machine the double magnetron sputtering target has high coating rate and dense film. Is a special equipment for chip resistance end coating. The coating yield is over 99%. The size and configuration an be customized according to customer requirements.Silver Mirror Production Line

The silver mirror production line uses chemical spraying method to plate the glass surface with silver film and copper film, and then paint one or two layers of paint film on it. available for all glass sizes. And widely used in the construction industry. The Leading silver mirror production line manufacturer in China.Plastic Decorative Plate Vacuum Coating Machine

Plastic decorative plate vacuum coating machine is the first choice equipment for decoration, toys, plastic and ceramic industries. The Leading manufacturer in China. High cost performance,we have team to jointly provide customers with high-tech, high-quality products and efficient, convenient and comprehensive pre-sales and after-sales professional services.High-grade Environmental Protection Copper-free Silver Mirror Equipment

Products from high-grade environmental protection copper-free silver mirror equipment can meet European CE standards,and silver mirror products are widely used in the construction industry. The whole production line adopts frequency conversion motor drive and running speed can be adjusted on color display screen.Plastic Vacuum Coating Machine

Plastic Vacuum Coating Machine has the advantages of reasonable structure, uniform film layer, good mirror quality, high pumping speed, short working cycle, high production efficiency, convenient operation, low energy consumption and stable performance. Widely used in the decoration, toys, plastic and ceramic industries. We have a top R&D team and Independent intellectual property.