English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

Short Working Cycle Plastic Vacuum Coating Machine Manufacturers

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Short Working Cycle Plastic Vacuum Coating Machine,Vacuum Coating Machine for Plastic,Aluminum Metalizing Machine,Silver Reflector Vacuum Plating Machine,Evaporative Coating Device, Our aim is "blazing new ground, Passing Value", in the future, we sincerely invite you to grow up with us and make a bright future together!

Short Working Cycle Plastic Vacuum Coating Machine, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

Hot Products

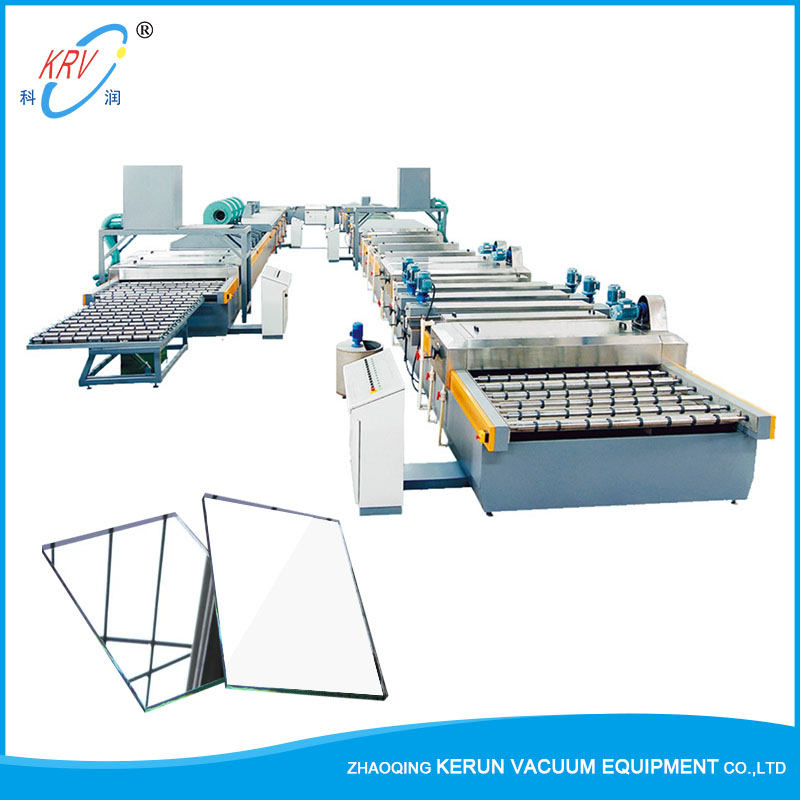

Tinted Glass Magnetron Coating Production Line

Tinted Glass Magnetron Coating Production Line, Stained glass magnetic coating production line adopts the principle of magnetron sputtering. The products from our company can meet European CE standards, 24K golden mirror and 18K golden mirror can be plated on transparent colorless flat glass. Multi-vacuum chambers and multi-sputtering chambers design are available.Magnetic Core Inductance Coating Production Line

The Magnetic core inductance coating production line greatly improves the bonding force and adhesion between the film layer and the workpiece uses magnetic sputtering to coat the surface of the magnetic core inductance with NI, AG, SN, CU and other materials, which are used as inductance lead welding. he whole process of the magnetic core inductance coating machine has no waste gas, no waste water discharge, and meets the national industrial requirements.Chip Resistance Terminal Magnetic Sputtering Coating Machine

Chip resistance Terminal Magnetic Sputtering Coating Machine the double magnetron sputtering target has high coating rate and dense film. Is a special equipment for chip resistance end coating. The coating yield is over 99%. The size and configuration an be customized according to customer requirements.Mobile Phone Decorative Film Magnetic Sputtering Coating Production Line

The mobile phone decorative film magnetic sputtering coating production line has the effect of firm film and strong adhesion. The transmittance and reflectivity can be adjusted according to the requirement. It widely used in mobile phone, electronics, audio, household appliances and other industries We have a top R&D team, cooperate with our superb manufacturing team, professional sales team and dedicated service team to jointly provide customers with high-tech.Silver Mirror Production Line

The silver mirror production line uses chemical spraying method to plate the glass surface with silver film and copper film, and then paint one or two layers of paint film on it. available for all glass sizes. And widely used in the construction industry. The Leading silver mirror production line manufacturer in China.Multi-arc Ion Coating Machine

The coating chamber of the multi-arc ion coating machine is made of high-quality stainless steel with a box-type front door structure. It can be configured with cylindrical or planar magnetron sputtering targets according to the requirement,and the first choice for the household appliance industry, size and configuration can be customized according to customer requirements.