English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

Coating Machine Manufacturers

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Coating Machine,Low Noise Magnetic Core Inductance Coating Machine,Glue Coating Machine,Multifunction Magnetic Core Inductance Coating Machine,Automatic Magnetic Core Inductance Coating Machine, Welcome around the world customers to make contact with us for enterprise and long-term cooperation. We're going to be your trustworthy partner and supplier of auto pieces and accessories in China.

Coating Machine, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

Hot Products

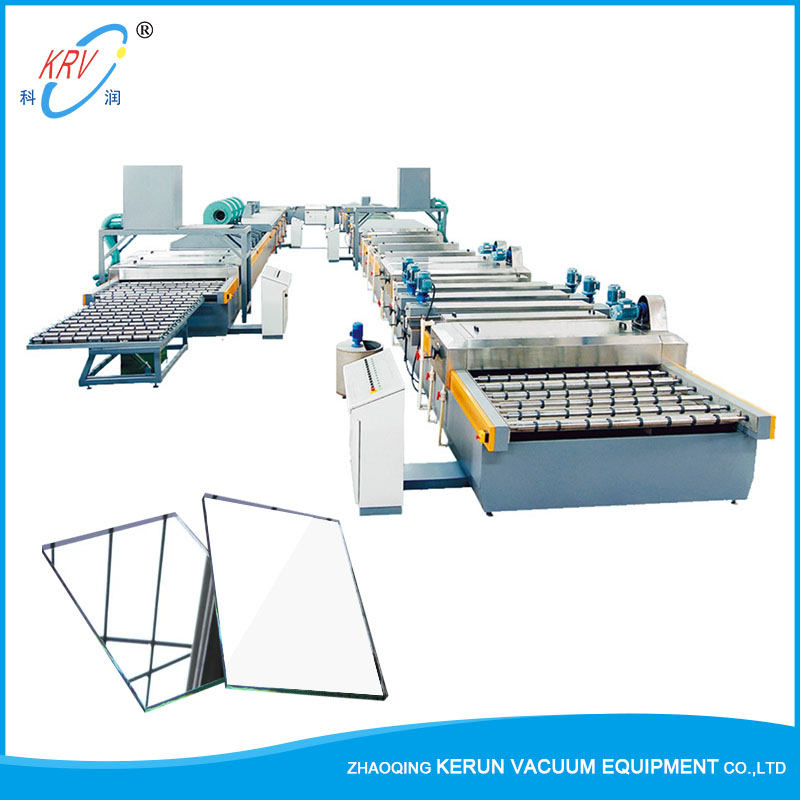

High-grade Silver Mirror Production Line

The high-grade silver mirror production line from the glass loading, then to glass washing, silver plating, copper plating, painting, baking, repainting, baking, washing, mark printing, and testing, finish in one time, the silver mirror can be packed after unloading. It is driven by a variable frequency speed regulation motor, and the running speed can be adjusted from the color display. The Leading silver mirror production line manufacturer in China.Multi-arc Magnetic Ion Coating Machine

Multi-arc magnetic ion coating machine uses programmable logic controller (PLC), automatic or manual optional. This series of equipment is mainly suitable for coating the surface of metal parts, hardware, etc. One layer or multi-layer metal film. For example, high-grade decorative films such as TIN film and imitation gold film, gold-doped film, gun black film, etc. Has been successfully exported to more than 20 countries including European and American markets and enjoys high reputation so far.Vacuum Leak Detector

The vacuum leak detector has the characteristics of simple and accurate leak detection, are necessary equipment for the vacuum machines manufacturers and the vacuum machine Users. It has been successfully exported to more than 20 countries including European and American markets and enjoys high reputation so far. We are the Leading manufacturer in China.High-grade Environmental Protection Copper-free Silver Mirror Production Line

High-grade environmental protection copper-free silver mirror production line adopt chemical spraying method to plate the glass surface with silver film, passivation protection, and then paint one or two layers of paint film. adopt quartz infrared heating tube for oven drying. size and configuration can be customized according to customer requirementsLOW-E Curtain Wall Glass Coating Equipment

We produced LOW-E curtain wall glass coating equipment which can reduce the emissivity of the glass from 0.84 to 0.1 or even lower, and reduce the radiation heat loss 90%. We have a top R&D team, cooperate with our superb manufacturing team Products from the LOW-E curtain wall glass coating equipment can meet European CE standards. The Leading manufacturer in China.Chip Resistance Terminal Magnetic Sputtering Coating Machine

Chip resistance Terminal Magnetic Sputtering Coating Machine the double magnetron sputtering target has high coating rate and dense film. Is a special equipment for chip resistance end coating. The coating yield is over 99%. The size and configuration an be customized according to customer requirements.